Application of AC-DC power adapter in industrial product field

In the field of industrial products, AC-DC power adapters are also widely used. First of all, AC/DC power modules play a role in providing stable power supply in the field of industrial automation. In the automated production process, various sensors, controllers, and actuators all need stable DC power supply. AC/DC power modules can convert alternating current into constant direct current to ensure the stable operation of the system.

At the same time, AC/DC power modules usually have functions such as overload protection, short-circuit protection, and overvoltage protection, which can effectively improve the stability and safety of the system. Secondly, AC/DC power modules have high efficiency in the field of industrial automation. Since industrial automation systems often require a large amount of power supply, the energy efficiency issue of power supplies has become an important consideration. AC/DC power modules usually have high conversion efficiency, which can minimize the loss of converting alternating current into direct current and improve the energy efficiency of the system. In addition, AC/DC power modules also have power factor correction function, which can reduce pollution to the power grid and improve the overall efficiency of the system.

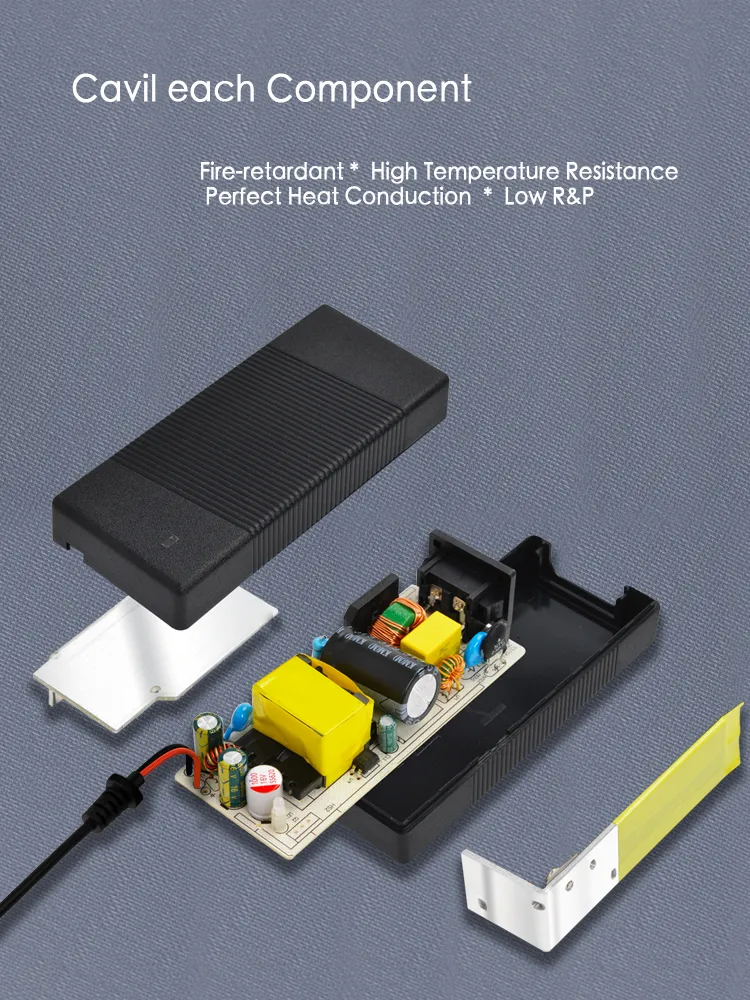

Finally, AC/DC power modules have high reliability in the field of industrial automation. Industrial automation systems often require long-term continuous operation, and the reliability requirements for power supplies are relatively high. AC/DC power modules adopt advanced power conversion technology and reliable electronic components, and have a long service life and a low failure rate. In addition, AC/DC power modules usually have overvoltage and overtemperature protection functions, which can protect the safe operation of the system under abnormal circumstances and improve the reliability of the system. How can AC-DC power adapters improve power conversion efficiency? Improving the power conversion efficiency of AC-DC power adapters can be achieved from multiple aspects. Choosing efficient components and materials is one of the keys. Using efficient components and materials can significantly improve the conversion efficiency of power adapters.

For example, choosing transformer materials and cores with high permeability and low loss, as well as components such as low-impedance rectifier diodes can improve the efficiency of power adapters. In addition, using high-efficiency magnetic components and low-loss insulating materials can also improve the efficiency of power adapters. Optimizing circuit design is also an important means to improve power conversion efficiency. By reducing voltage and current losses in the circuit, optimizing circuit layout and wiring, and reducing line impedance, the conversion efficiency of power adapters can be improved. In addition, adopting appropriate filtering circuits and EMC protection measures can reduce electromagnetic interference and energy loss and improve the efficiency of power adapters. Reducing no-load power consumption can also improve efficiency. No-load power consumption refers to the power consumption of a power adapter when no device is connected. Reducing no-load power consumption can be achieved by reducing the standby power consumption of the power adapter and adopting timing control and other methods. In addition, using soft start technology, intelligent control strategies and other means can also reduce the no-load power consumption of power adapters and thereby improve their efficiency. Adopting switching power supply technology can significantly improve the conversion efficiency of power adapters and reduce volume and weight. At the same time, appropriately adjusting parameters such as switching frequency and duty cycle can further optimize the performance of power adapters. Strengthening heat dissipation design can effectively reduce the temperature rise of power adapters, reduce heat loss and energy loss, and thereby improve their conversion efficiency.