Blog

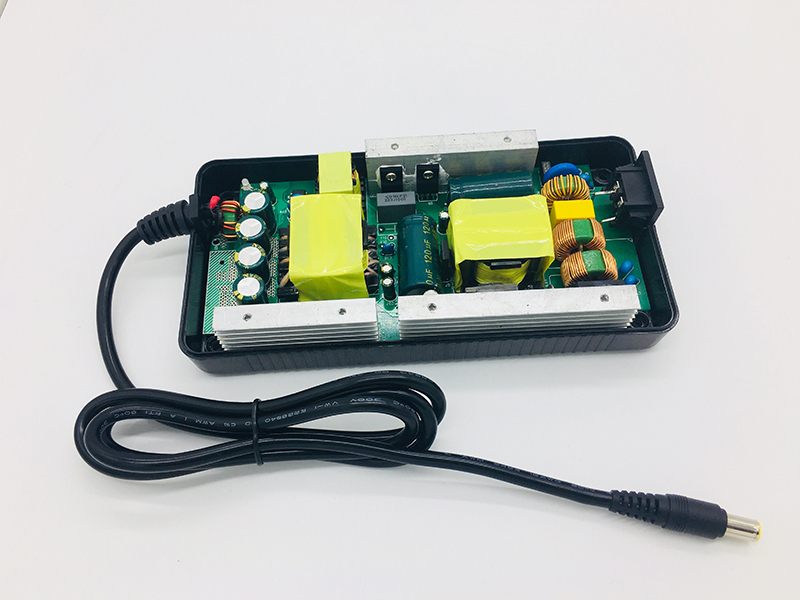

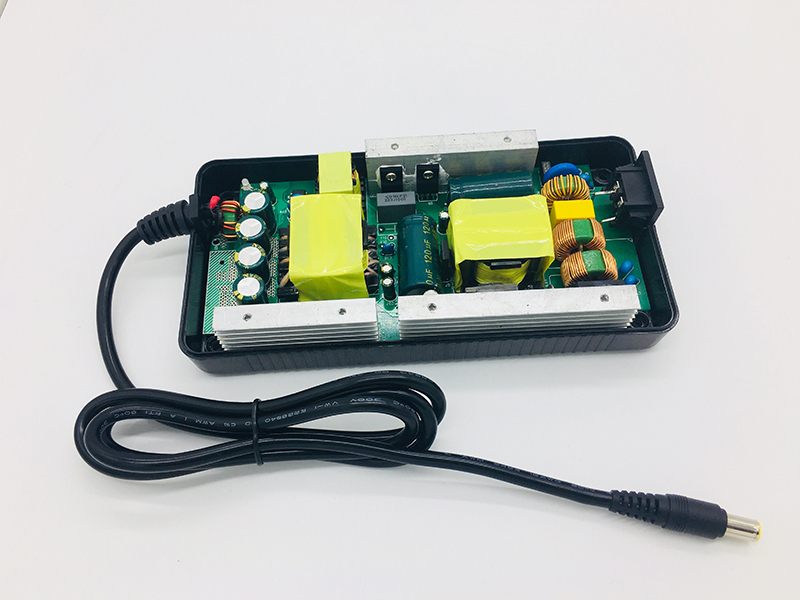

The material of power adapter shell

Views : 938

Update time : 2023-05-17 15:23:48

The shell of the power adapter is usually made of plastic, although some industrial power supplies use metal shell. The common important power adapter shell material is ABS material, ABS+PC material, pure PC material.

1.PC material

Pure PC material has ultra-high strength and elastic coefficient, with a wide range of temperature can be used. (general ABS material can only be used at -25 degrees to 60 degrees) Also PC material has high transparency and free dyeing, so that the power adapter easy to do a variety of colors very well. in addition, this material also has fatigue resistance, weather resistance, tasteless and odorless harmless to human body, It is conform to health and safety.

2.ABS material

This material is low strength and non-temperature resistance,generally the use of the maximum temperature can not exceed 60 degrees Celsius.Compared with PC material,the ABS have a large difference. And ABS is mostly used in household appliances.

3.Synthetic materials of ABS and PC

Take the above two characteristics, has excellent molding processing performance, good fluidity, high strength. ABS+PC material is easy to process with stable processing size and good gloss. Besides, this tpye of Synthetic materials is easy to paint, coloring, can also be sprayed metal, electroplating, welding and bonding and other secondary processing properties. Due to the characteristics combined with the characteristics of its three components, it has excellent comprehensive performance and becomes one of the preferred plastics for electrical components, home appliances, computers and instruments.

In the choice of power adapter shell material, basically are pure PC material and PC+ABS, although the cost will be higher than before and the price of power adapter will be different. In terms of the environmental protection and safety, ABS is no longer match the current market demand! So the power adapter manufacturer reminds you that when you choose the power adapter, try to choose a large manufacturer to buy!

1.PC material

Pure PC material has ultra-high strength and elastic coefficient, with a wide range of temperature can be used. (general ABS material can only be used at -25 degrees to 60 degrees) Also PC material has high transparency and free dyeing, so that the power adapter easy to do a variety of colors very well. in addition, this material also has fatigue resistance, weather resistance, tasteless and odorless harmless to human body, It is conform to health and safety.

2.ABS material

This material is low strength and non-temperature resistance,generally the use of the maximum temperature can not exceed 60 degrees Celsius.Compared with PC material,the ABS have a large difference. And ABS is mostly used in household appliances.

3.Synthetic materials of ABS and PC

Take the above two characteristics, has excellent molding processing performance, good fluidity, high strength. ABS+PC material is easy to process with stable processing size and good gloss. Besides, this tpye of Synthetic materials is easy to paint, coloring, can also be sprayed metal, electroplating, welding and bonding and other secondary processing properties. Due to the characteristics combined with the characteristics of its three components, it has excellent comprehensive performance and becomes one of the preferred plastics for electrical components, home appliances, computers and instruments.

In the choice of power adapter shell material, basically are pure PC material and PC+ABS, although the cost will be higher than before and the price of power adapter will be different. In terms of the environmental protection and safety, ABS is no longer match the current market demand! So the power adapter manufacturer reminds you that when you choose the power adapter, try to choose a large manufacturer to buy!